Ever watched your profits slowly bleed out while your containers sit in customs? Or tried explaining to a frustrated client why their order is delayed…again? If you’re nodding your head, you’re probably still trapped in the overseas fabrication cycle.

The Real Cost Behind That “Bargain” Quote

Let’s be honest about what that overseas fabrication quote really means. Sure, the upfront price looks amazing – that’s the hook. But what about the three-month lead time? Or those customs delays that somehow never make it into the sales pitch?

The reality is that cheap fabrication comes with expensive problems. When your overseas supplier misunderstands your specifications, that’s not just a minor inconvenience – it’s a costly rework that eats into your margins. And those quality rejections that happen way too often? Each one represents hours of project management headaches and disappointed customers.

American fabrication might show a higher initial price tag, but the math changes dramatically when you calculate what those overseas “savings” actually cost you in the long run.

From Months to Weeks: The Lead Time Revolution

Remember when you promised that client you’d deliver in eight weeks, knowing full well your overseas fabricator quoted a six-week turnaround that would inevitably stretch to twelve? We’ve all been there.

With US-based stainless steel fabrication, those delivery nightmares become a thing of the past. Instead of the standard 14-18 week overseas wait (plus shipping, plus customs), domestic fabrication typically runs 3-6 weeks. That’s not just faster – it’s transformative for your business model.

Think about what this means for your cash flow. Instead of having capital tied up for months in products still sitting on a ship somewhere, you can turn inventory faster, bill clients sooner, and respond to market changes with agility that overseas-dependent competitors can only dream about.

Goodbye Importing Headaches, Hello Simplicity

Have you become an unwilling expert in customs declarations? Know the name of your customs broker better than your kids’ teachers? That’s not what you signed up for when you started your business.

The importing process has a way of consuming time you should be spending on growth. Those mysterious fees that appear out of nowhere. The shipping containers that vanish into the logistics void for weeks. The constant currency calculations as exchange rates fluctuate. It’s exhausting – and entirely unnecessary.

Domestic fabrication eliminates this entire category of stress from your business. No more customs paperwork. No surprise tariffs. No international wire transfers with hefty fees. Just straightforward business with partners who speak your language, understand your needs, and operate under the same laws and regulations.

The Copycat Problem Nobody Talks About

Here’s the uncomfortable truth most businesses learn too late: sending your proprietary designs overseas is basically setting up your future competition.

I’ve watched it happen too many times. A company spends years perfecting an innovative stainless steel component. They send detailed specifications to an overseas fabricator to save on production costs. Within 18 months, identical products appear on the market at lower prices – often made by a “new company” with suspicious connections to their original fabricator.

With US-based fabrication, your intellectual property remains protected by enforceable laws and business relationships built on mutual respect rather than just opportunism. That breakthrough design that gives you a competitive edge? It stays your edge.

Order What You Need, Not What Ships Cheapest

“You’ll save on shipping if you fill the container.” How many times have you heard that line? And how many times has it led to ordering far more inventory than you actually needed?

Overseas fabrication creates perverse incentives to overorder, tying up capital in excess inventory that sits gathering dust while incurring storage costs. That extra 30-40% inventory doesn’t just represent cash you can’t use – it’s also warehouse space you’re paying for, plus the very real risk that designs will change before you use it all.

Domestic fabrication flips this model completely. Need just 25 units to test market demand? No problem. Want to make a small modification to your next batch? Easy. Need to rapidly scale up production when a product takes off? Your fabricator is a phone call away, not a 14-hour flight.

Supporting American Manufacturing Just Makes Sense

This isn’t about flag-waving. It’s about smart business strategy. When you invest in US-based fabrication, you’re strengthening a supply chain you actually rely on – one that won’t suddenly become inaccessible during the next global disruption.

You’re also keeping dollars circulating in an economy where your own customers live and work. There’s a beautiful circular logic to supporting domestic manufacturing: the fabrication jobs you help sustain create consumers who might someday purchase products containing your components.

In an era of increasing international tensions, having critical fabrication capabilities in friendly hands isn’t just patriotic – it’s prudent business planning.

Communication That Actually Works

Try explaining a complex stainless steel specification change at 2 AM on a crackly international call with someone whose technical English is limited. Not fun, is it?

Communication barriers with overseas fabricators aren’t just frustrating – they’re expensive. Every misunderstood specification leads to wasted materials, rejected components, and timeline delays. The inability to visit the shop floor means you can’t catch problems early when they’re still inexpensive to fix.

US fabricators speak your language, understand your expectations, and share your cultural business norms. You can actually meet face-to-face, review prototypes together, and build the kind of relationship that leads to proactive problem-solving rather than after-the-fact damage control.

The Lean Inventory Advantage

US-based fabrication enables a truly lean approach to inventory management. Instead of the massive safety stocks required with overseas suppliers (typically 60-80% higher than domestic needs), you can operate with minimal inventory and maximum flexibility.

This doesn’t just mean less warehouse space and reduced carrying costs. It means your business becomes more responsive to market changes. When customer preferences shift, you’re not stuck with mountains of outdated inventory. When an improvement becomes possible, you can implement it immediately rather than “using up” obsolete components first.

In today’s fast-moving market, this agility is often the difference between thriving businesses and struggling ones.

Quality You Can Count On

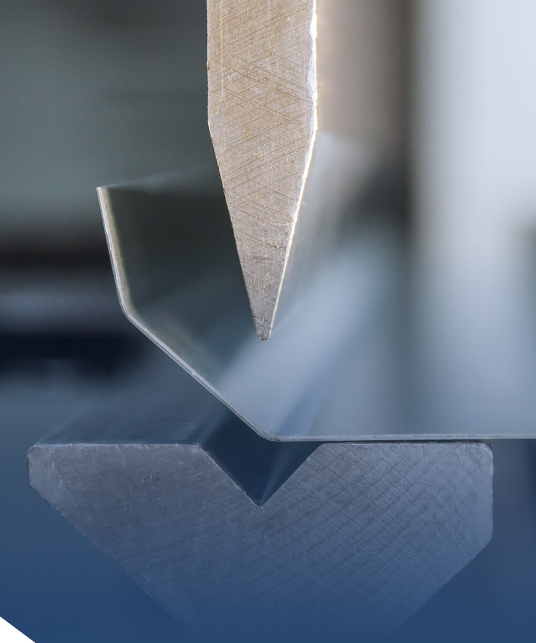

There’s something special about American-made stainless steel components. It’s the precision of the cuts. The consistency of the welds. The attention to finish quality. The adherence to specifications that matches drawings exactly rather than “approximately.”

This quality difference isn’t just aesthetic – though that matters too. It’s functional. Components that fit together perfectly. Assemblies that don’t require field modifications. Products that last longer and perform better under stress.

The 10-15% premium you might pay for this quality typically saves you 25-30% in reduced warranty claims, field service calls, and customer satisfaction issues. This isn’t speculation – it’s the financial reality I’ve seen across dozens of businesses that made the switch to domestic fabrication.

Production Schedules You Can Actually Trust

“We’ll update you when it ships” isn’t a production schedule. It’s an admission that the manufacturer has no real control or visibility into their process.

With US-based fabrication, schedules mean something. When your fabricator says three weeks, they mean three weeks – not “somewhere between two and six months depending on factors we don’t control.”

This predictability transforms how you can operate your business. You can make promises to customers with confidence. You can plan installations without expensive contingencies. You can coordinate multiple suppliers without building in weeks of buffer time.

The Bottom Line: Total Cost Wins

Here’s the unvarnished truth: When you calculate ALL the costs associated with overseas vs. domestic stainless steel fabrication, the US option often emerges as the clear financial winner.

The overseas base price might be 15-25% lower, but then add:

- Shipping costs 10x higher than domestic

- Quality rejection rates 3x higher

- Management time 3-4x greater

- Inventory carrying costs 2-3x higher

- IP protection risks that could cost you your market position

This isn’t about patriotism or convenience – though those are nice bonuses. It’s about hard-nosed business math that increasingly favors domestic production, especially for precision components like stainless steel fabrication.

Making the Switch: Your Next Steps

Ready to escape the overseas fabrication trap? Start by identifying which components cause the most consistent headaches. These are your prime candidates for reshoring.

Next, find US-based fabricators with experience in your specific requirements. Begin with a smaller project to test the relationship, quality, and communication before committing your most critical components.

Be sure to track ALL expenses related to both options – not just the invoice amount, but all the soft costs like management time, quality issues, and inventory carrying.

Most importantly, view this as building a partnership, not just placing an order. The best US fabricators become extensions of your own team, contributing ideas and innovations that create competitive advantages beyond just the components themselves.

The Future Is Domestic

The fabrication game is changing fast. Global supply chains have proven fragile. Overseas labor costs continue rising. Quality expectations keep increasing. Smart businesses aren’t asking if they should transition to US-based stainless steel fabrication—they’re asking how quickly they can make the switch.

Your customers may never know exactly where your stainless steel components come from, but they’ll absolutely notice the difference in quality, reliability, and your ability to deliver consistently on time.

Ready to discuss your specific stainless steel fabrication needs? Contact us today and discover the US manufacturing advantage firsthand.