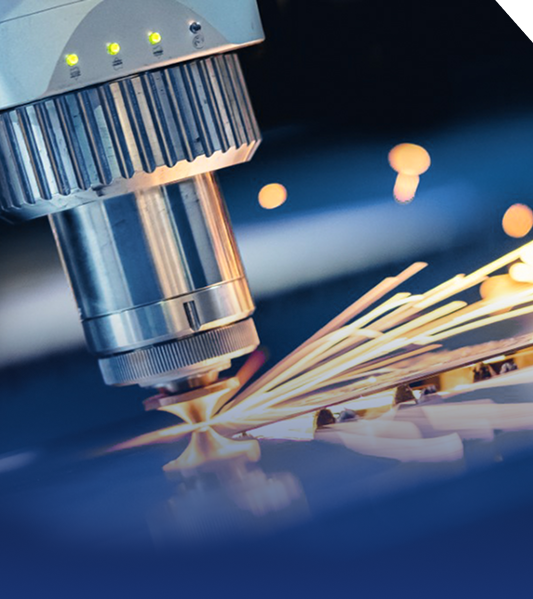

Laser Cutting

Precision CNC Laser Cutting: Where Technology Meets Craftsmanship

When it comes to modern metal fabrication, precision is everything. Today’s manufacturing demands tighter tolerances, cleaner edges, and faster turnaround times than ever before. That’s why we’ve invested in cutting-edge CNC laser technology to complement our 100+ years of metalworking expertise. The marriage of advanced equipment and deep fabrication knowledge creates results that simply can’t be matched by shops that only offer one or the other.

The Power of Modern Laser Cutting

Let’s cut through the marketing fluff and talk real capabilities. Our high-powered laser system delivers exceptional results across multiple materials:

- Steel: Clean cuts up to 1/2" thick with minimal heat-affected zones and edge quality that often eliminates secondary operations.

- Stainless Steel: Pristine edges up to 1/4" with virtually no discoloration, critical for both aesthetic and corrosion-resistant applications.

- Aluminum: Precision cutting up to 1/8" with mirror-like finish potential and the ability to process reflective materials that challenge lesser systems.

- The difference between our precision laser capabilities and conventional cutting? It's like comparing digital photography to a disposable camera. Both capture images, but one delivers professional results every time.

The Technology Behind the Results

What makes modern laser cutting so revolutionary compared to older methods? Several factors come together to create a superior fabrication process:

- Beam Quality: The focused energy creates an incredibly precise cutting point, allowing for intricate details down to 0.03" in thin materials.

- Computer Control: Our CAD/CAM integration means your digital design translates directly to the finished product with minimal variation.

- Speed Advantage: Cut rates up to 3x faster than plasma and 5x faster than traditional mechanical methods.

- Energy Efficiency: Lower power consumption per part compared to conventional methods, reducing the carbon footprint of your manufacturing process

Serving the Heart of America: Oklahoma, Kansas, and Arkansas

While our Tulsa headquarters has been our home for many years, our precision fabrication services extend throughout the region. Businesses across Oklahoma, Kansas, and Arkansas trust us with their most demanding projects because:

- Regional Understanding: We know the unique needs of Mid-American manufacturers and energy producers.

- Logistics Advantage: Our central location means faster delivery and easier collaboration.

- Shared Values: Like our neighbors in Kansas and Arkansas, we believe in straight talk, fair pricing, and standing behind our work.

Why Regional Manufacturers Choose Our Laser Cutting Services

With over 100 years of combined experience in the fabrication industry, we’ve learned what matters most to clients:

- Accuracy When It Counts: Our CNC laser maintains ±0.005" tolerances even on complex geometries—meaning your parts fit right the first time, every time.

- Speed Without Compromise: Rapid production without sacrificing quality. Quick turnaround matters in today's just-in-time manufacturing environment.

- Customer Service: We go above and beyond to make sure our customers are happy with our work.

- Design Flexibility: From simple brackets to intricate components with complex internal features that would be impossible to produce with traditional methods.

- Consistency Across Production Runs: Whether you need 5 parts or 5,000, the last piece will be identical to the first—something hand fabrication simply can't guarantee.

Real-World Applications That Showcase Precision

Our team has helped countless businesses across Oklahoma, Kansas, and Arkansas solve complex fabrication challenges:

- Oil & Gas Components: Precision-cut flanges, brackets, and custom parts.

- Agricultural Equipment: Custom parts for farm machinery that keep the heartland's equipment running through harvest season.

- Architectural Elements: Decorative panels with intricate patterns that transform ordinary spaces into showcases.

- Custom Signage: Business identifiers with crisp logos and text that reflect your brand's commitment to quality.

- Industrial Equipment: Replacement parts manufactured to exact specifications—often exceeding OEM standards.

- Prototype Development: Rapid iteration of designs for new product development, accelerating your time to market.

Real Talk: When to Choose Laser Cutting

Not every project needs laser precision, and we’ll be straight with you about that. Laser cutting makes the most financial and practical sense when:

- Your tolerances are tight (±0.005″ or less)

- You need clean edges without secondary finishing

- Your designs include intricate details or small holes

- You’re working with materials that are difficult to cut conventionally

- You need rapid prototyping or short-run production

- Your application requires minimal heat distortion Material strength is critical (thermal cutting preserves more base material properties)